Behind the distinctive black sheen of Lãnh Mỹ A lies a process that is as technical as it is time-intensive. At the core is mặc nưa, a natural dye extracted from the fruit of the Diospyros mollis tree, indigenous to southern Vietnam. Unlike synthetic pigments, mặc nưa delivers a deep, layered black with subtle undertones of ink, soil, and wood. It is not applied. It is absorbed, bonded with the silk through repetition and precision.

Credit: Travellive

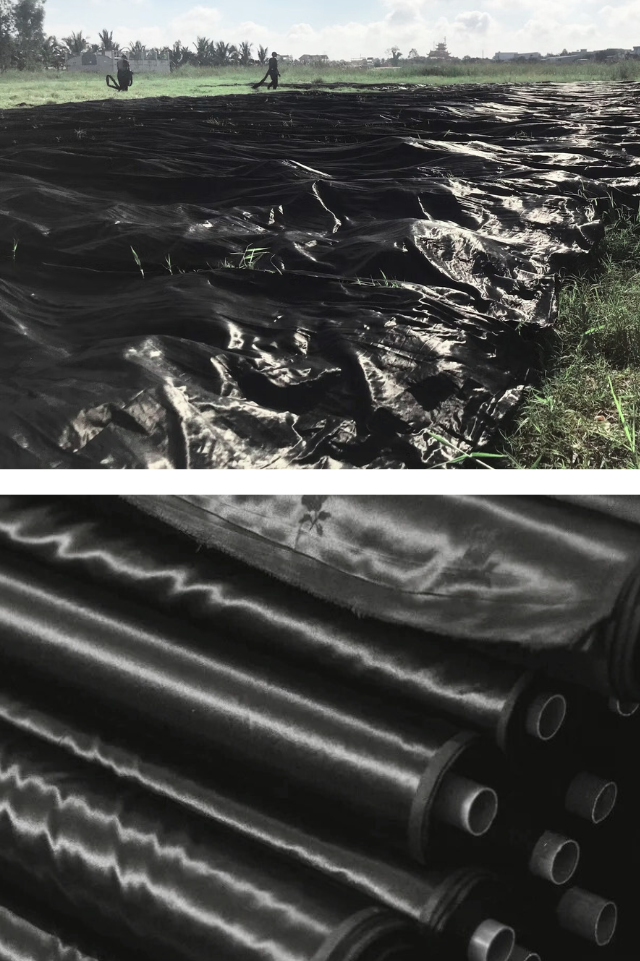

The dyeing process begins during the rainy season, when the fruit’s tannin levels are highest. After harvest, the fruit is crushed and fermented, sometimes aged, to enhance its pigment. The preparation is entirely natural: no chemicals, no artificial additives. Each bolt of Lãnh Mỹ A silk undergoes a meticulous transformation, requiring more than eitghty individual dyeing cycles. For every metre of fabric, approximately 100 kilograms of fruit are used. The silk is dipped, dried, and re-dipped, sometimes up to forty times in a single round. Each round involves immersion, sun-drying, and rinsing in water sourced from the Mekong River. Artisans rely only on environmental cues: light, humidity, and instinct passed down through generations.

Credit: Travellive

Every stage is controlled. Dyeing is done only in the cooler hours of the day; by noon, the fabric is moved to shade. After the third dyeing round, the silk is hand-beaten to soften the fibres and allow deeper penetration of the dye. The Mekong’s mineral-rich water is critical in preserving the fabric’s natural lustre. The result is a silk that is rich in texture, with a black finish that is matte yet luminous, durable, and visually compelling.

To qualify as true Lãnh Mỹ A, the silk must meet three criteria: it must be 100% Vietnamese mulberry silk; it must be handwoven using the satin 8 method; and it must be dyed exclusively with mặc nưa. No compromises are permitted. These standards ensure that each piece maintains its cultural authenticity and technical quality.

Credit: Travellive (first picture) – L’officiel magazine (second picture)

Mặc nưa also stands apart for its ecological integrity. It comes from the land, returns to the land. Where synthetic blacks leave behind residues and metals, mặc nưa vanishes cleanly into the earth. It represents a low-impact, circular process, reflecting a tradition that existed long before sustainability became a market concern. This intimacy with nature is its quiet strength and also its fragility. Decades of deforestation have diminished the mặc nưa tree. The labour-intensive nature of the work also makes it difficult to scale within modern production models. In an era of automated textile manufacturing, mặc nưa offers a counterpoint, emphasising rarity, intentionality, and environmental alignment. It is not designed for mass replication. It is built to endure.

In the hands of the artisans of Tân Châu, the dye is more than medium. It is the foundation of a material legacy that continues to define Vietnamese textile craftsmanship at its highest standard. Mặc nưa is not merely the method by which black is created; it is the reason black holds meaning.